“The ability to print directly on offset coated media without any specialty treatments using High Fusion Ink has enabled us to achieve full color personalization across our direct mail applications.”

– Thierry Ngoma, Vprint Plant Manager

CHANGING MARKET DEMANDS

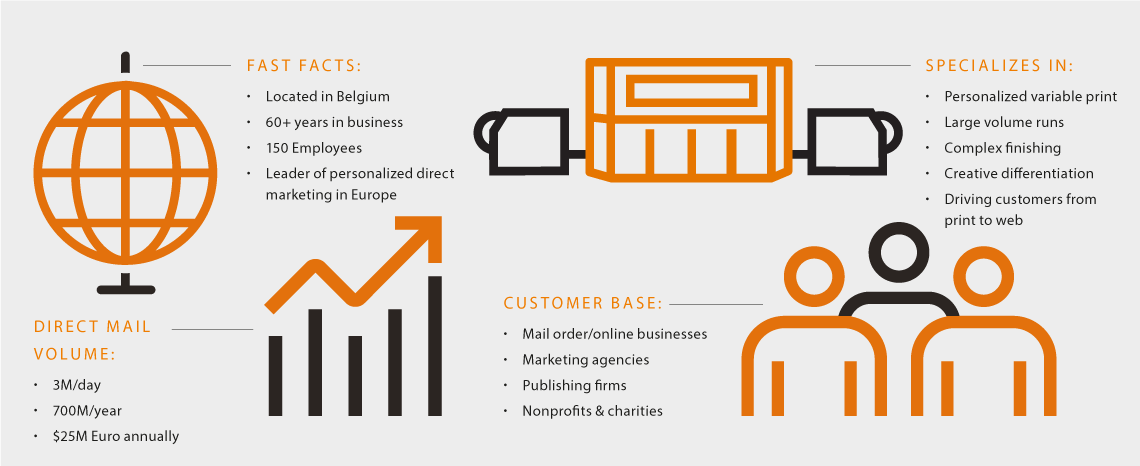

Direct mail is a quickly evolving market where high-impact, results-generating personalization is a must. Vprint’s customers wanted highly personalized mailers capable of bringing data to life in 100% personalized color – with new ways to drive people to the web.

INCORPORATING NEW TECHNOLOGY INTO EXISTING PROCESSES

At the time, Vprint was running up to

3 million pieces per day, on three web offset presses. They were then personalizing them using 16 custom-built finishing lines designed with locked-in-place inkjet heads. While cost-effective and efficient, that workflow limited personalization to certain areas of the document and in almost every case, it could only be done in black ink and low quality.

Vprint knew they needed to find a way to meet growing and changing demands by investing in technologies that would work with their existing finishing processes. It was also important to find a solution that would increase their capabilities and allow them to add color anywhere, giving their customers more flexibility and high quality, without the added cost of specialty stocks.

THE XEROX® TRIVOR® 2400 INKJET PRESS DELIVERS

After evaluating ways to bring agile personalization and new production capabilities into their manufacturing process – all while remaining competitive – Vprint selected the Xerox® Trivor® 2400 HF Inkjet Press.

Their decision was based on speed, output quality, and the fact that the press achieves highly personalized inkjet printing on a wide range of offset coated stocks without requiring any primers or pretreatments. This lets Vprint use the same media they run on their web presses (matte, silk, and gloss

up to 9 pt) for consistency, while adding full-color personalization and leveraging their existing finishing processes. Post-processing treatments, such as glue, are not affected because there are no primers on the paper.

“ The flexibility, impressive print quality, and speed that the Trivor 2400 delivers cannot be matched by any other device on the market. It allows us to offer new value, new solutions, and more personalization for our customers. This is the future for us.”

– Raphael Baillieul , Vprint Sales Manager

VPrint’s Trivor® 2400 HF Inkjet Press

VPrint’s Trivor® 2400 HF Inkjet Presswas installed in January of 2017.

They quickly reached volumes of 6M

prints per month and volume continues

to grow as they engage more clients

with their new capabilities.

NEW CAPABILITIES AND EXTRAORDINARY RESULTS

Vprint was able to quickly and seamlessly integrate the Xerox® Trivor® 2400 HF Inkjet Press into their existing manufacturing processes, expanding into new, high-value personalization capabilities without expanding costs.

In their first year of operation, they successfully utilized Trivor to sell new hybrid applications and drive an increase in profitable business, including jobs that run white paper-in vs requiring offset shells.

CUSTOMERS FIND SUCCESS WITH HYBRID APPLICATIONS

The flexibility of Trivor has enabled creative hybrid solutions that combine the inkjet production of dynamic personalized content with either offset or digital printing for higher area coverage sections.

This type of production environment allows customers to take advantage of the effectiveness of full digital personalization while maintaining the

economics of offset for static elements.

With these new capabilities, Vprint has been able to balance volume, cost, and quality in a whole new way.

One hybrid retail catalog has generated such an impressive boost in online sales, the client has repeated the same campaign seven times! The inside of the catalog features variable pages filled with personalized product recommendations based the customer’s purchase history while the static cover pages are printed on offset.

Highly personalized applications utilizing a variety of stocks, such as loyalty card mailers, can also be brought together using this approach. The possibilities are virtually endless.

COMPLETELY CUSTOMIZED MULTIPRESS MAGAZINES DELIVER INCREDIBLE RETURNS

As a result of partnership between Xerox, Vprint, and Dataline, these magazines were fully personalized with stories, articles, images, and text based on the recipient’s job title, location, and interests. 30,300 hard copy and digital versions were created with unique PURLs to measure year-over-year results – which were astounding.

• € 218,000 increased revenue

• Website hits increased 4X

• Page views/visitor increased 3X